Edit: We sold out of these last copies in two days. Sorry!

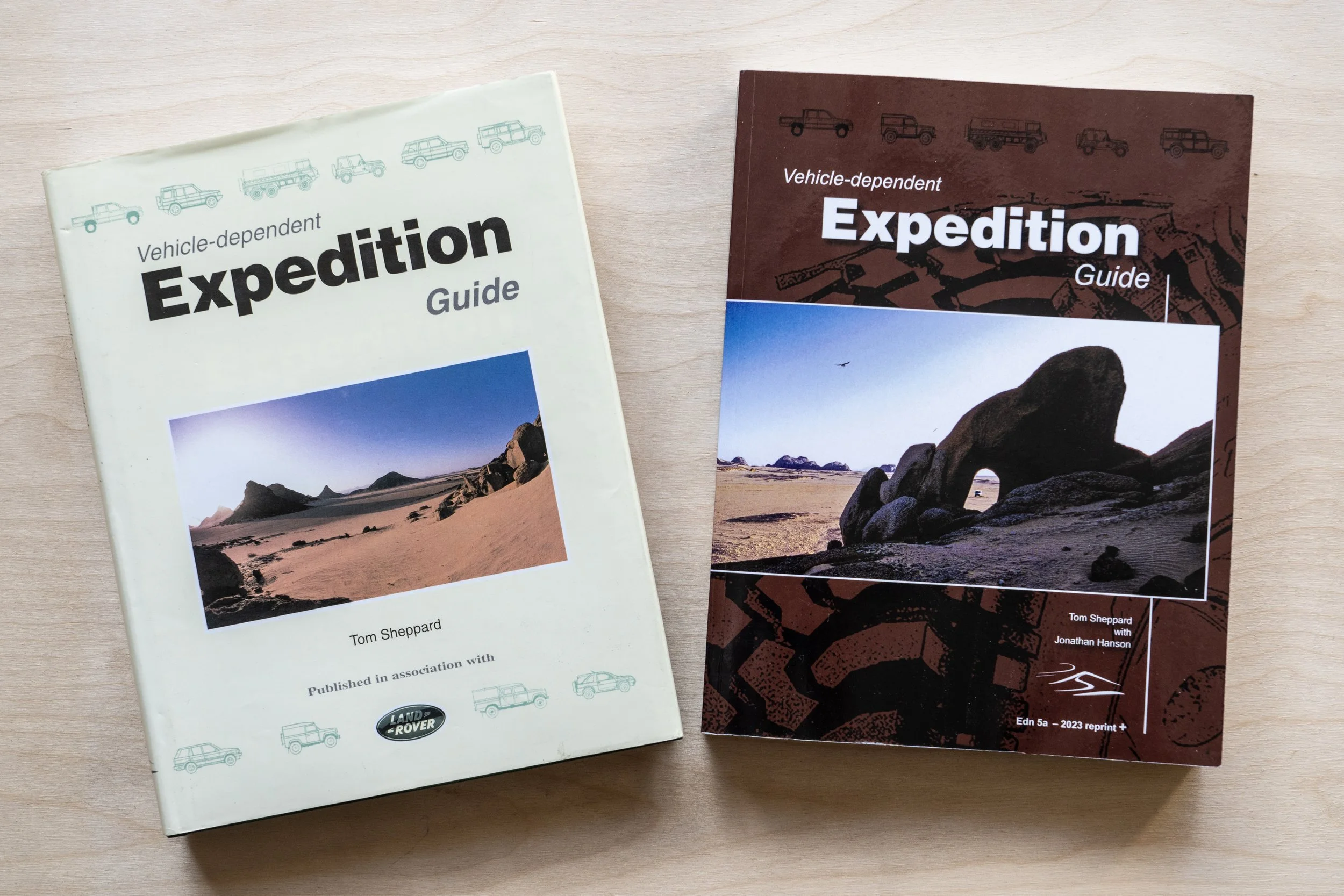

Nearly 30 years ago, Tom Sheppard published the first edition of the Vehicle-dependent Expedition Guide under the auspices of Land Rover. The book quickly gained a reputation as the definitive guide for anyone planning remote vehicle-based travel, whether a weekend jaunt in Montana or a month-long research expedition in Mauritania.

I bought my first copy in 1999, and instantly fell under its spell: a fanatically detailed, practical guide that also inspired dreams of far horizons. The author’s background as an RAF test pilot showed in his meticulous dives not only into vehicles, driving, provisioning, and shipping, but clothing, communications, group leadership—even an investigation into the chemistry of automotive oils that could have come from a BP engineer. “Definitive” was not merely ad-speak for this book. And those images of Land Rovers crossing Sahara dunes kept me up at night forging far-fetched plans—many of which were subsequently realized.

Sheppard soon assumed full responsibility for the VDEG (as its author and fans refer to it), giving him much greater editorial freedom, and he kept abreast of new vehicles and technologies with frequent revisions and new editions.

In 2015 I was honored when Tom, by then a good friend, asked me to come on board. Together we significantly enlarged the VDEG to over 600 pages; four solid pounds covering the massive increase in overland-oriented products introduced in the previous decade, as well as new driveline, navigation, and communication innovations. That edition itself has been updated several times, most recently with an increase in physical size and larger print and photographs.

As Tom closed in on his 90th birthday, he mentioned the possibility of slowing down a bit (although he still rides his BMW from Great Offley into Hitchin for grocery shopping). And finally he let me know that the current print run would be the last. The Vehicle-dependent Expedition Guide is now out of stock on both sides of the Atlantic.

However, a well-known 4x4 trainer in the UK, who specializes in teaching special forces units and who uses both VDEG and Tom’s equally authoritative 4x4 Driving, offered to pay up front for one last run of 100 copies to keep providing to his students, at least for a while. Tom decided to increase the run to 140 copies and offer the extras for sale.

Thus I’m happy—if a bit conflicted as well—to announce a very limited opportunity to purchase one of the last 40 copies of the bible of overland travel. I have a list of those already signed up; if you’re willing to commit to a copy as well please contact me via email. This will on be a first-come, first-served basis, of course. We’re limiting the offer to one copy per customer please. The orders and payment will go directly to Tom in the UK once the books are printed; given the current favorable exchange rate, the final price will be little, if at all, higher than the last $80 cover price and U.S. shipping.