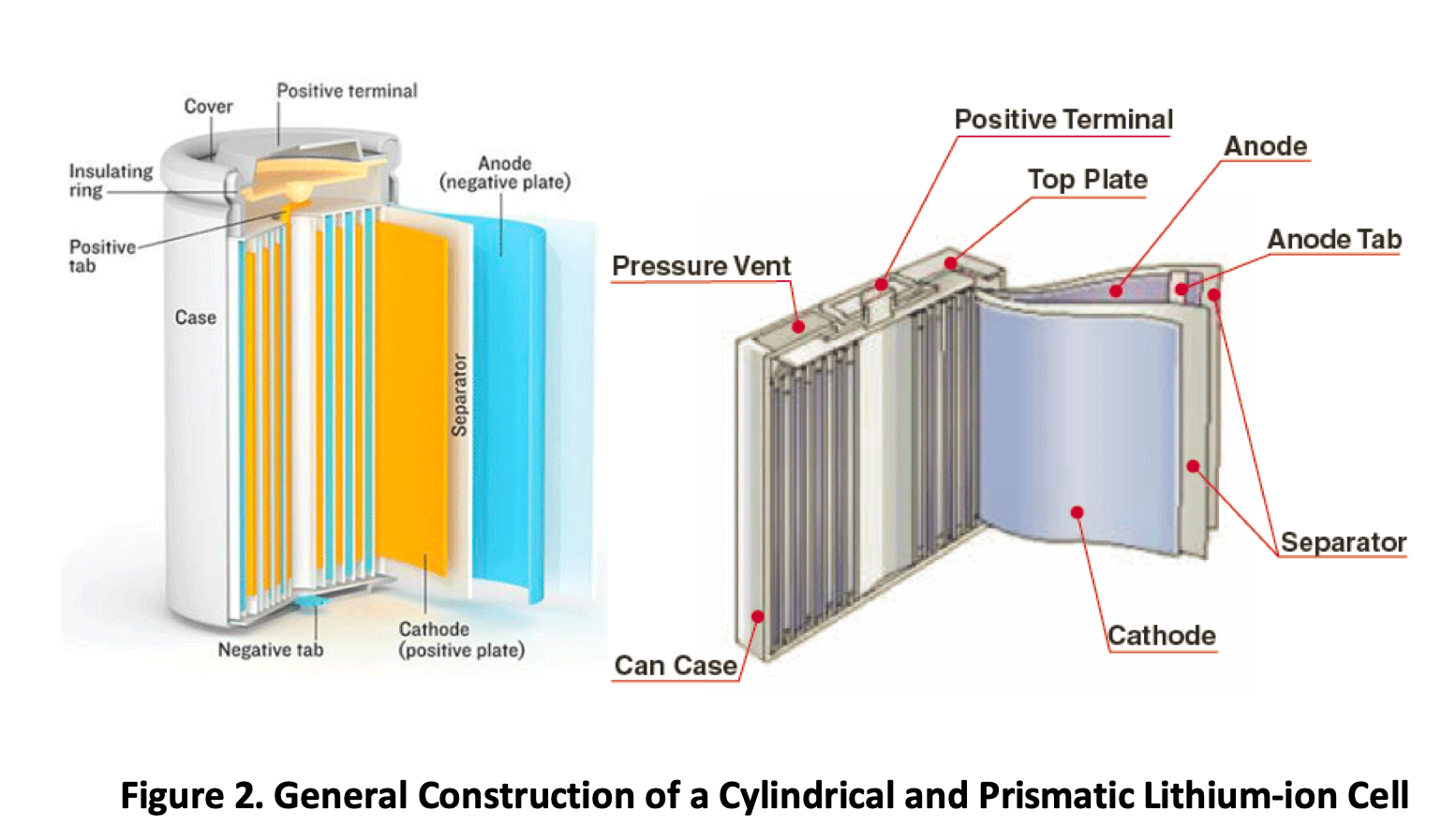

If you research LiFePO4 starting and deep-cycle batteries beyond the glossy ads, you’ll soon uncover the two major types of component construction used in their manufacture: cylindrical cells or prism cells.

Cylindrical cells look just as their name implies. Cut open a battery built with them and it will look like several dozen standard D-cells, connected end to end and arranged in rows and columns.

Prism cells for automotive use are larger and look more like flat bricks; typically such cells are 3.2 volts each, thus four of them connected in series create a 12.8-volt battery. (This is how Antigravity Batteries builds their LiFePO4 units.)

Which is better? Not surprisingly, manufacturers using cylindrical cells say cylindrical cells are better, and those using prism cells say prism cells are better. In truth, a high-quality battery can be built using either construction. The difference is in details, and the emphasis each manufacturer places on the respective characteristics of each type.

Cylindrical cells are more amenable to volume production, and are thus less expensive. They handle internal pressures well, and the multiplicity of cells in a typical battery means that if one cell fails, the battery can continue to operate. However, they take up more space, and are more quickly affected by temperature swings—since each cell is small and has an air space around it, they will heat up more quickly or drop below a critical lower temperature more quickly. (On the other hand, of course, they will recover from over- or under-threshold extremes more quickly as well.) A battery made with cylindrical cells necessitates a multitude of mechanical connections to build the completed unit, increasing the potential for internal structural issues due to vibration and impact.

Prism cells are more difficult and thus expensive to manufacture. Their chief advantage lies in a greater ability to tolerate over-charging as well as over-discharging. Thanks to their configuration they also boast superior energy density compared to cylindrical cells, which means greater flexibility for the manufacturer, and potentially lighter weight in the completed battery. In terms of thermal management, their compact form means a prism-cell automotive battery will take significantly longer to reach either a high or low temperature threshold—and, of course, longer to recover from that threshold.

Several configurations of prismatic LiFePO4 cells

According to Scott Schafer at Antigravity, the company’s first LiFePO4 batteries were cylindrical-cell models—but they switched to prism cells some time ago. Why? “Reliability,” according to Scott. He noticed that the higher-end manufacturers of cells were using prism technology more and more, and indeed, since switching their offerings, Antigravity has experienced a drop in warranty claims, which he attributes largely to that greater tolerance for over-charging and over-discharging. That was enough to convince me.