One of the most basic and effective tools for self-recovery in sand, mud, or snow is what we generically call the sand ladder or sand mat. For decades these typically comprised a cut-down section of WWII surplus PSP (Perforated Steel Planking, also called Marsden matting), originally designed to be linked together to build impromptu runways on boggy ground. Shoved edge on against a tire buried in sand, PSP provides a ramp on which the vehicle can gain traction and climb (especially when combined with some judicious pre-shoveling). PSP is effective but heavy, thus the popularity of a modern version—PAP—made from aluminum.

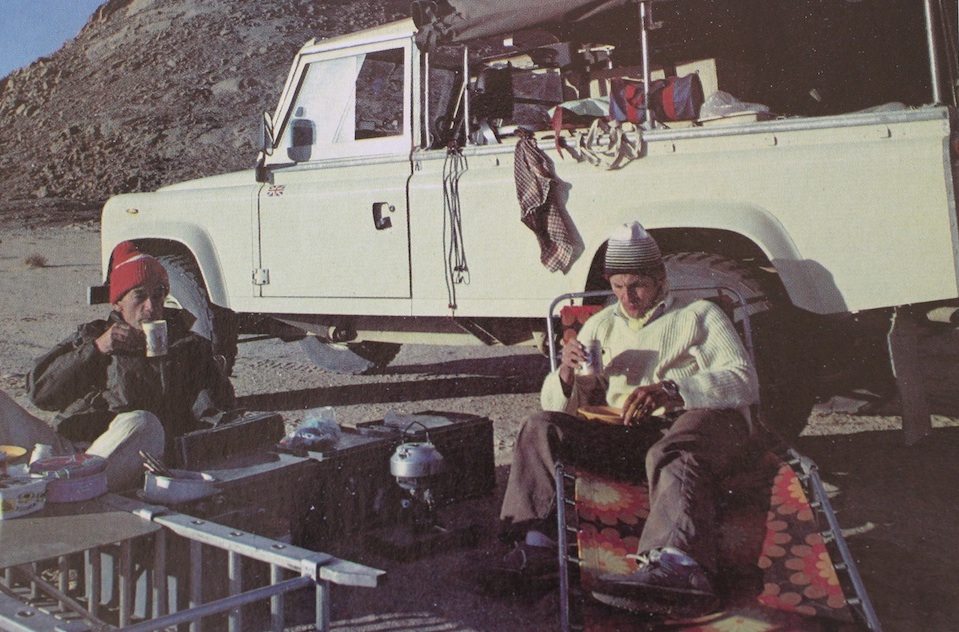

Semi-rigid material such as PSP and PAP works well to provide flotation and traction in soft substrates, but is not stiff enough to be used to bridge a deep ditch, or to function as a ramp to surmount a vertical ledge, unless doubled—in which case the normal complement of two allows only one wheel to be supported. Sahara explorer Tom Sheppard surmounted this problem decades ago by simply ordering a pair of custom-made ladder sections such as one would use at home, but with extra-deep side rails and rungs spaced just 15cm apart. Each section was sturdy enough to provide bridging support for one side of a loaded Land Rover—and with some connecting pieces also served as a convenient framework for kitchen furniture.

Today, plastic sand mats such as the excellent Max Trax offer a lightweight (18 pounds per pair) alternative to traditional versions; however, the Max Trax is still insufficiently rigid to be used as a bridging ladder unless doubled. The connoisseur’s choice for combined traction and bridging duty has for some time been the excellent Mantec bridging ladder (known as a bridgy by the abbreviating Brits), a beautifully trussed and welded structure of aluminum more than strong enough to support a fully laden expedition vehicle. But the Mantec ladders currently run about $650 per pair when you can find them this side of the Pond, and their bulk and weight—42 pounds for the two of them—is a handicap, too.

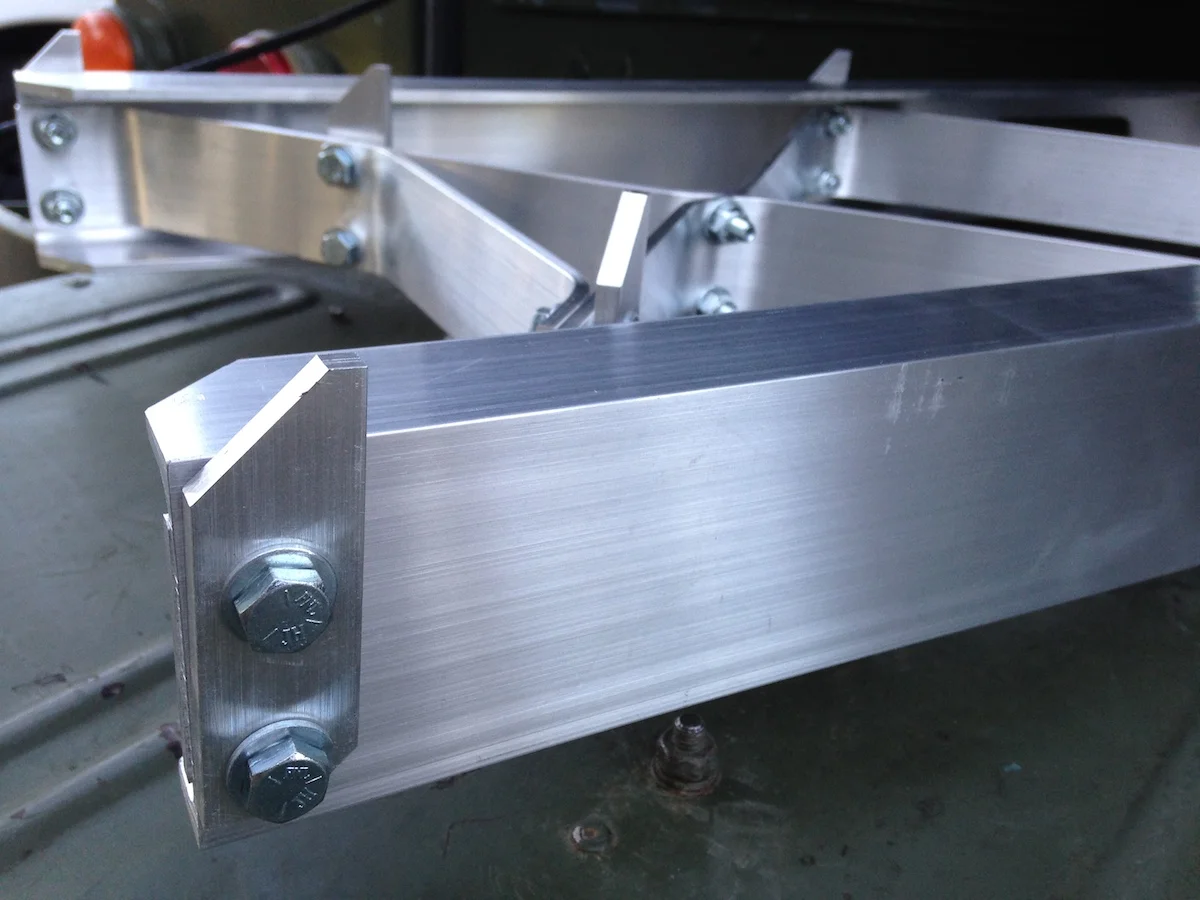

However, a significantly more affordable ($349) aluminum bridging ladder is on the horizon, thanks to Jeremy Plantinga of the newly formed Crux Offroad. Jeremy contacted me a year ago and showed me a few prototype designs before finalizing a design and shipping me this set—which comes disassembled via UPS, saving yet a bit more in shipping costs (a flat $30 to the lower 48).

The main structure of the Crux ladder comprises two 48-inch-long U-shaped side channels and two W-shaped cross treads, with a brace at each end and a total of 12 aluminum grip spikes that extend beneath the rails. The ladder is designed so the tire contacts the cross treads only after passing the ends of the side channels, to reduce the chance of kick-up. The instructions say assembly takes about an hour; I did the first one in 25 minutes and the second in 20. The side channels can be assembled with the U either in or out, depending on the width of your tires—with the U facing in the ladders appear more than wide enough for either the 235/85x16 ATs on our Tacoma or the 255/85x16s on the FJ40. The modular design means it will be easy for the company to tweak dimensions for different applications.

Mantec on the left, Crux on the right

In a quick visual comparison the Crux ladder lacks the monolithic support of the Mantec. It's obvious the Crux will offer less flotation in very soft sand, mud, or snow; on the other hand its open cross treads should significantly enhance traction and reduce kick-out when climbing. At 34 pounds per pair the Crux ladders are 20 percent lighter than the Mantecs (although they are also 20 percent shorter). Last year on the Continental Divide, when an FJ Cruiser pulling a trailer got stalled on some uphill ice, a pair of Max Trax we deployed simply zipped right under the tires when power was applied; the plastic offered no purchase against the ice. I’m willing to bet the grip spikes on the Crux ladders will do better in the same situation. For bridging, Jeremy rates the Crux ladders at 2,000 pounds each, which, given the insight I’ve had into his failure testing, seems appropriately conservative, and more than enough to support most full-size pickups, or a Land Cruiser or Jeep Wrangler Unlimited. Jeremy has plans to develop accessories such as table or bench tops and legs, which would enhance their versatility.

I’m looking forward to field-testing the Crux ladders, and expect they’ll perform well. If you’re intrigued too, they will be debuting and available at the Overland Expo in Mormon Lake next month. I plan to hand over my set to the Camel Trophy blokes to see what they can come up with for on-site testing.

The company's nascent website is here.

Update: I've had a little time to play with them. Supporting the front wheels of a Defender 110 in the middle of the span, the Crux ladders showed essentially zero deflection. Impressive . . .

Another update: The Crux ladders nest securely, located by the traction spikes. When joined, the adjacent handle holes make it easy to carry both ladders with one hand.