Like more experienced people of my acquaintance (you know who you are, Jim), I’m hyper-vigilant about spooling my winch lines correctly.

There are solid practical reasons for this: A winch line that is spooled neatly, tightly, and under load is far less likely to kink (if steel) or snarl, and there is less risk of the line diving down through the wraps below during a strenuous recovery. A neatly and tightly spooled winch line is smaller in overall diameter on the drum than a loosely and sloppily spooled line, thus retaining more of the winch’s rated power. During most straight winch pulls, a properly spooled winch line will practically re-spool itself automatically as it follows the path of least resistance across the drum. Finally, if you’re ever forced by circumstances to pull out your line all the way down to the bottom layer during a recovery, those tightly spaced first few wraps are less likely to slip.

However, I have to admit something: There’s also a significant OCD component to my own diligence. I can’t sleep when I get back from a trip or training until I know that winch cable is restored to perfect alignment. A winch cable lined up in snug parallel rows like a Marine drill team—or the Rockettes, take your pick—just looks so much better than, well, this:

Please pause while I catch my breath.

(Of course, ironically, a winch that’s been bolted on strictly as a poseur accessory, with factory-spooled line, will look just as tidy. We must then count on our frayed and faded Dyneema and well-burnished eyelet or hook to set us apart as real users.)

For years I preached the gospel of properly spooled winch line—at the Overland Expo, during NPTC evaluations, in private training sessions, and on guided trips. The total of my converts surely rivaled that of an obscure middle eastern carpenter from a few centuries back.

Then, recently, horror struck.

On a random day on a random overlanding forum, I came across a post titled something like “Cross-winding your winch cable.” The author of the post—clearly a goat-horned demonic agent sent from the Underworld—claimed that by spooling one’s winch cable in great angled swoops across the drum, the chances of the line diving were eliminated, since the line was never layed parallel.

There was a photo.

OMG.

My stomach lurched. My pulse jumped. It was . . . indescribable. Lazily spooled winch lines were nothing compared with this . . . this deliberate travesty.

Staring at the awful image, I tried to calm myself. With shaking fingers I straightened my computer on my desk. I straightened my phone. I lined up my pens, my flashlights, my knives. They were all already straight but I straightened them again. I re-coiled my Macbook’s power cord into a perfect whorl. Was my desk crooked? I nudged it into perfect alignment with the floorboards.

It didn’t help. I needed a drink. I stumbled to the kitchen. Daiquiri? Its elegance and mathematical symmetry (2:1:1) beckoned. Clumsily I gathered the components—no, this was taking too long. I flung the top off the crystal decanter and chugged directly. Rum ran down my chin and spilled onto my shirt, onto the countertop. I licked it up. Oh the degradation. I tried to slow my breathing.

Okay . . . better.

Back at the computer, I replied to the goat-horned demon, politely, that no one should consider trying such a “technique,” and that no professional would recommend it.

The GHD responded, “Oh really? How about this then?” And included a link to a page on the Samson Rope website.

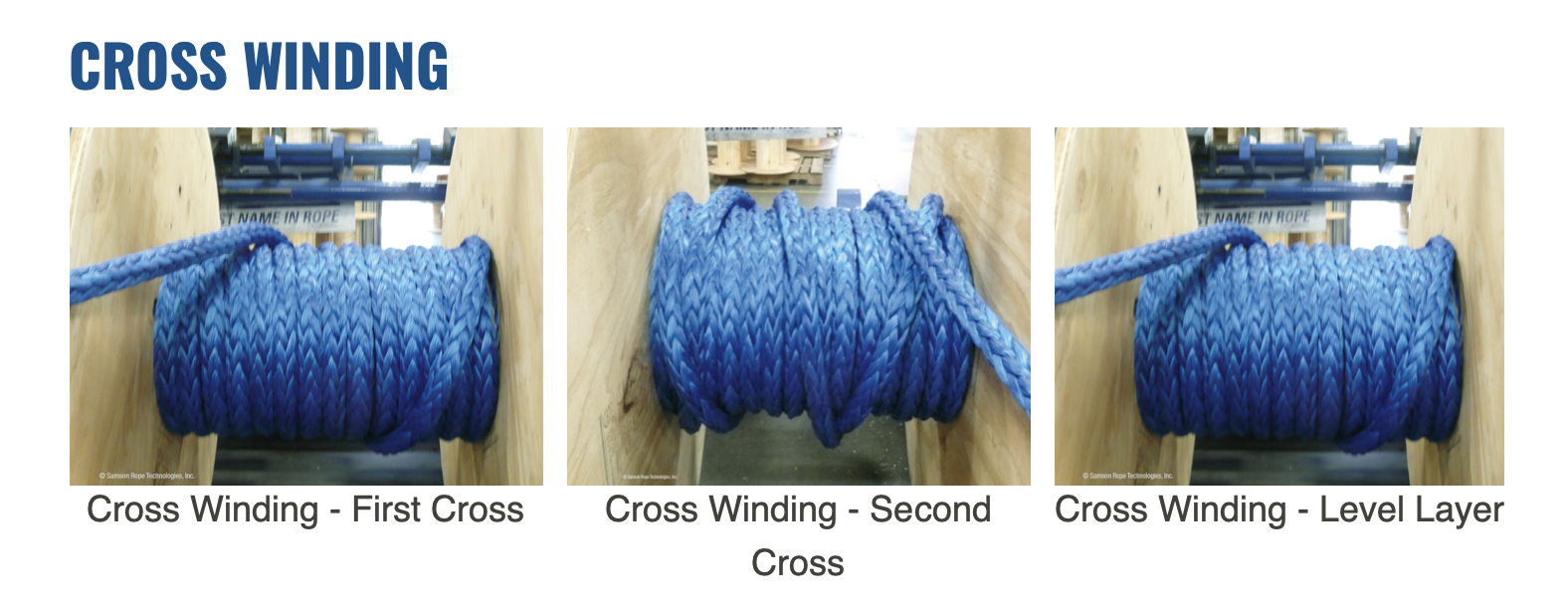

I felt a queasy stirring of doubt, but clicked on the link—and there, on the website of one of the most respected makers of rope and winch line on the planet, was a series of photos explaining how to cross-wind synthetic winch line when spooling it.

I wondered briefly if nitroglycerin pills were available over the counter.

Instead I looked around the web, and found another reference to cross-winding from the Australian company Schillings, and in fact uncovered mentions of the practice in forum archives from over a decade ago.

Okay. Deep breath. I firmly escorted OCD Jonathan outside and locked the door, then sat down and thought critically about this technique. As the Samson site described it, you wind on two layers of line in the normal fashion, then drag the line across the drum as it spools, creating two layers of criss-crossed line. Then two more flat layers, then more criss-crossing, until the line is fully spooled. All in an effort to prevent the winch line diving between layers when under a load—which, it seemed on the surface, it might accomplish.

Or would it? Given the instructions to alternate two layers of parallel windings with the crossings, it would still be critical to ensure those parallel layers were tight, or your criss-crossed line would still happily dive between them as it was pressed into the spool when one of the parallel layers above it was pulled tight under a load—perhaps creating an even worse snarl. Additionally, the Samson instructions specified “50 pounds of tension.” That’s not very much—when I respool I employ a minimum of several hundred pounds of tension.

I thought some more. First, I noted that I have never personally had a winch line dive between layers with my “normally” spooled winches, nor have I seen it happen on winches belonging to the far more experienced people I’ve had the luck to train with and learn from. This led me to believe that, except in rare circumstances, the problem was only a problem with poorly spooled lines—i.e. spooled with insufficient tension—and that someone who experienced it because of poor technique and adopted cross-winding as a fix would probably experience it even with cross-winding.

Second, it’s obvious that cross-winding will take up more space on a winch drum than parallel winding, reducing the power of the winch with each unneeded layer, and requiring more line to be pulled off the drum to achieve the same strength. Also, how could you possibly neatly wind two parallel layers atop two cross-wound layers?

There are other issues. In a side-pull scenario, when the criss-cossed layer is uncovered I’d expect the line to jump across the drum with some force, at minimum creating a sharp jerk in what should be a smooth operation. Also I’d expect line speed to increase and decrease as either a crossed line or a parallel line is tensioned.

In the end I remained firmly unconvinced, if not actually calling BS. But was I now an outlier? A dinosaur? I sent the Samson link around to a few friends and associates, including luminaries such as ex-Camel Trophy team members. No one who responded thought cross-winding made sense. Andy Dacey, a director at Wildtrackers in the UK, who not only trains military units in four-wheel-drive techniques but is also a forester and thus extremely familiar with ropes and rope handling, believes the Samson page is aimed at those who spool their winch lines by hand, under very little tension—thus the “50 pound” reference. He also noted that a line under high tension pulled over the line one layer lower at near right angles would put extreme stress on one point, flattening it there. (If you use a synthetic-line-equipped winch frequently, you might notice the lower wraps sometimes look strangely squashed; doing that across the line doesn’t seem like a great idea.)

Andy told me he has no intention of cross-winding his winches. Any of them.

I don’t either.

Now if you’ll excuse me I have to go let OCD Jonathan back in.

He’ll be relieved.

Easy, Jonathan. For illustration purposes only.