Thinking outside the box

For a short time after I got out of college, in the mid-1980s, I sold Toyotas for a living to pay off student debts (I was pretty sure I wouldn’t be doing so working as a freelance writer . . .). When talking to customers about Toyota trucks or the Land Cruiser, I always made sure to point out the fully boxed frame, and contrast it to the open C-channel frames then standard on American pickups. In those days you commonly saw Chevy and Ford trucks with the cab accent line offset from the bed line by an inch or more, due to frame flex that eventually settled in permanently. I’d take the customer on a demo drive, and put one front wheel up on a high curb to get a rear wheel off the ground, then show them the bed perfectly aligned with the cab. If they still had any doubts, I showed them a stack of articles I’d saved from the local newspaper, which covered the massive problems the Arizona Game and Fish Department had been having with their current issue half-ton Chevrolet trucks—cracked frames and broken motor mounts had reduced the serviceable numbers in the fleet by almost half.

At that time, the corporate line from Ford and Chevy was, “The frames are designed to flex (Italics mine) to maintain a comfortable ride and keep all tires on the ground as part of the suspension design.” Riiiiight.

The magnitude of the about face in the last 20 years would be amusing if it weren’t so annoying. Beginning in the late 90s and this century, American pickup manufacturers began producing (and heavily hyping) frames with higher and higher levels of torsional rigidity, culminating in the splendid fully boxed chassis now standard on all half-ton Ford, Chevrolet, and Ram pickups, and being introduced on 3/4 and 1-ton models as well. Even some crossmembers are boxed these days, in addition to being formed along with the side rails from high-strength and ultra-high-strength steels. Clearly the Big Three discovered that they could maintain a “comfortable ride” and still build a stronger, more durable truck.

It’s all over their ads these days:

Here's Chevy promoting the new boxed frame on its 3/4-ton pickup:

Meanwhile, over at Toyota . . .

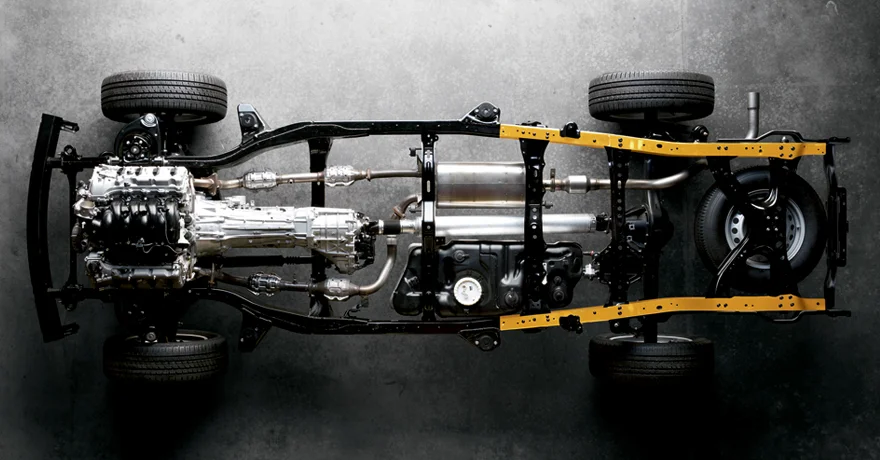

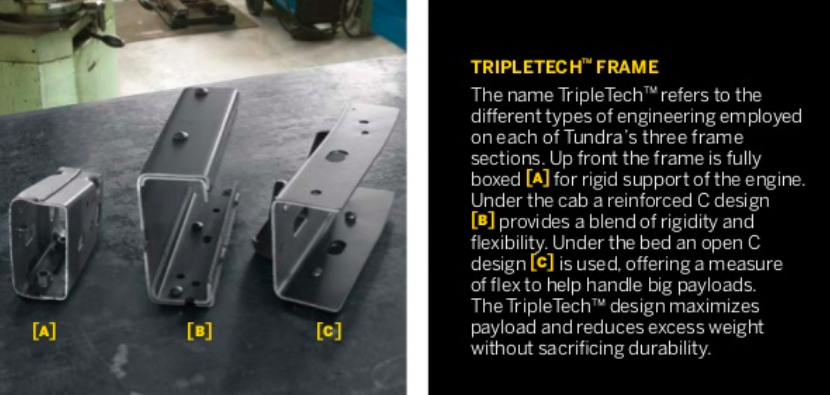

First, the full-size Tundra arrived in 2008 with a foundation grandly described by the company as a “Triple-Tech” frame—which, as I wrote about here, turned out to be an open C-channel frame with a bit of boxing under the engine. Next, the second-generation Tacoma was introduced. Gone was the fully boxed frame that had been under every compact Toyota truck for four decades; in its place was . . . an open C-channel frame with a bit of boxing under the engine. The redesigned 2016 Tacoma retains this configuration.

Toyota’s explanation for this? I’m paraphrasing various official websites and quotes to several reviewers, but the gist is accurate: “The frames are designed to flex (Italics mine) to maintain a comfortable ride and keep all tires on the ground as part of the suspension design.”

Let's parse the caption in the ad above. First, Toyota tells us that the front of the frame is boxed for "rigid support of the engine"—obviously a heavy item. Then they tell us the rear of the frame is an open C, "offering a measure of flex to help handle big payloads." Okay Toyota, so what if I want to carry, say, an engine in the bed of my truck? And that middle part cracks me up. A "blend of rigidity and flexibility." So, it's . . . sorta rigid?

There’s a back story here that I believe might be behind this. Many of the fully boxed frames under first-generation Tacomas and Tundras developed severe rust problems, to the point that Toyota has paid to have thousands of them replaced, at no-doubt hideous expense. Toyota blamed the problems on sub-standard steel from a provider, but there was little doubt the issue was, at the very least, exaggerated by water getting trapped inside the frame rails. I wonder if Toyota execs decided to eliminate that problem and save money at the same time by switching to an open-channel frame and tagging it with a fancy name.

Let’s be clear—a boxed frame is better in virtually every way than an open-channel frame. The strongest structural member there is is a tube. That’s why race cars and race trucks are built with tubes, not open C-channel members.

The proper place to engineer suspension compliance is in the suspension, not the structure responsible for supporting both the suspension and all the running gear and bodywork on the vehicle. The Toyota Land Cruiser (including the pickup) and Hilux, the Land Rover Defender, the Mercedes-Benz G-Wagen, the Jeep Wrangler—all employ fully boxed frames. So does the new Chevrolet Colorado, set to take a chunk out of the Tacoma’s market share. The military’s HMMWV? A fully boxed frame.

Heck, even HMMWV scale models have fully boxed frames:

In fact, the only exception I can think of in high-quality four-wheel-drive vehicles is the Mercedes Unimog, the chassis of which has deliberately been engineered to incorporate a degree of flexibility. Suffice to say that the massive Unimog is dealing with an entirely different set of parameters than a half or 3/4-ton pickup (as are oft-referred to semi-truck trailers).

Proponents—or apologists—point out that the steel in open-channel frames is thicker than that in boxed frames. To use the vernacular: Duh. It has to be thicker to maintain even a semblance of rigidity. You could argue that an open-channel frame is intrinsically more resistant to rust, given the thicker material and the lack of potential crannies to trap water and crud. But Toyota’s failures along these lines don’t mean boxed frames are inferior, simply that those particular frames were not designed properly to keep out water or to let it drain. For proof look at all the other boxed chassis on the market with no such problems, and indeed Toyota’s own earlier trucks that had no issues.

Some claim that boxed frames are heavier, which is simply untrue. A boxed frame can actually be made lighter than an open-channel frame of identical torsional rigidity.

The only legitimate advantage to an open-channel frame (besides, obviously, lower cost) is that it is simpler to bolt things to. There’s just a single thickness of steel, and easy access to drill and place bolts and nuts to attach anything from a bracket for a suspension air bag to a replacement utility cargo bed. On a boxed frame you must drill through two thicknesses of steel a couple inches apart, and use much longer bolts. A minor and infrequently encountered issue for most of us.

I’m curious—apprehensive might be a better word—to see what Toyota does with its next generations of U.S.-spec trucks. Now that the company has gone down the open-channel “better than a boxed frame” path, it would mean a loss of face to go ‘backwards’ to a better design. (Think the next Hilux will show up with an open-channel frame? I bet not.) The irony would be thick if the company that showed U.S. manufacturers how to build a better truck frame fell permanently by the wayside in competitive design.

There's an old saying that is doubly appropriate here: "Sometimes it's good to think outside the box. Other times it's better to stay in there and have someone tape it shut."