It happens again and again. I’ll be cruising some forum or another, and in the camping section there’ll be a new thread titled, “Recommendation for a good tent?”

Oh boy! Buddy, you’ve come to the right place, I’ll think. I’ve been testing and reviewing tents for three decades (and using them for a lot longer); I own, at last count, 16 of them, and I can induce that Dear God, get me away from this lunatic look of panic in the eyes of any conversation partner at a party with talk of thread counts, aluminum alloys, and the stunning superiority of silicone fly treatment over polyurethane. “Wait!” I grab her arm as she sidles away. “Did you know that ‘denier’ refers to the weight in grams of nine thousand meters of a single filament of the fabric?” “Really? How nice. Oh golly!” (Glances at watch.) “I just remembered I have an appointment for an appendectomy! Bye!”

Where was I? Right: So I click on the thread, and the first line is something like: “I need a tent for motorcycle travel—what’s good for under $100?”

My shoulders sag, I look at the ceiling and close my eyes. Sigh . . .

Think about this for a moment. When you are traveling and camping, your tent is your home—your last line of defense against rain, wind, cold, and bugs after a long day driving or riding. You can survive with a cheap sleeping bag and a good tent, but if your $39.95 Costco dome tent leaks in a shower, or collapses in a breeze, the best sleeping bag in the world will not keep you comfortable—or, in marginal conditions, even safe. Sleeping well is critical to maintaining health on the road, and alertness while riding or driving. So, how can I put this diplomatically? It’s stupid to economize on your tent.

I learned this lesson early on—like, when I was 10 or 11. Desperate to own a “tent,” I spent—what, $2.99 at the time?—on one of those ghastly plastic ‘tube tents’ to carry in my military surplus rucksack. A single breezy night at Seven Falls north of Tucson, with my German shepherd, convinced me—and the dog—of the hilarity of the concept of sleeping inside an open-ended trash bag. It was a lesson that morphed into an appreciation for the value of good equipment of all kinds—a philosophy that was reinforced during my years as a sea kayaking guide, when I accumulated a cheap-tent repair kit of heroic proportions for those clients who refused to believe a tent should cost more than lunch.

So what goes into making a high-quality tent, and how do you shop smartly to make sure you’re getting one?

While there is some overlap, tents really need to be divided into ‘backpacking’ designs and larger ‘family’ models. Weight is critical on the former, so material choices need to be more sophisticated than on the latter, where a few pounds makes little difference. I’m going to concentrate on lightweight tents here, so let’s look at markers for a tent that will keep you safe and comfortable no matter what the conditions. Note that these parameters will change for family tents; they are not universal. (Much of the following information, and more, is in the Vehicle-dependent Expedition Guide, fourth edition.)

Poles. This is your first indicator of quality. Do not buy a tent equipped with fiberglass poles joined by metal ferrules; they will not stand up to even moderate breezes and can splinter asunder when stressed. You want aluminum alloy poles from either Easton or DAC (Dongah Corporation). These companies use alloys in the 7000 series and argue at length whether 7001 is better than 7075, etc. All are excellent when properly heat treated. Ultralightweight tents might use poles as small in diameter as 8.5mm (.334”); those for larger three- or four-season tents will be 9mm to 12mm. Some manufacturers slightly pre-bend the poles before heat-treating; this reduces the initial stress on the pole when pitching the tent. (The only possible higher aspiration in tent poles would be the extremely expensive carbon-fiber versions from Easton, available on the company’s lightest three-season tents—I note they’re not provided with their four-season models, which makes me wonder if they’re completely sorted yet.)

Aluminum alloy poles, such as these from Easton, are the only proper choice for a quality tent.

Fly. The separate outer, waterproof layer of your tent will be made from either nylon or polyester. Nylon is stronger by about 15 percent, and more elastic. However, it is also much more susceptible to UV degradation, and is hygroscopic—the fabric absorbs (and chemically bonds to) water. Either will work, but overall, unless nylon is expensively silicone-coated (see below), polyester is probably superior. The weight of flysheet (and many other) fabrics is measured in denier, which really is calculated as I told my captive conversation partner above. Practically speaking, a flysheet made from 10-denier material would be very light indeed; most lightweight tents use 30 to 70-denier fly fabric.

Coating. Since neither nylon nor polyester flysheet material is waterproof on its own, it must be coated, and this is what separates cheap-to-good tents from really superior tents. The former employ polyurethane, which is applied to the underside of the fly. Why the underside? Because polyurethane is even more susceptible to UV degradation than the material. To keep the fabric above the coating from being soaked (and to add a bit of UV protection), it is coated on top with a DWR (durable water-repellent) treatment, usually a fluoropolymer applied at the production stage. Unfortunately the ‘durable’ bit is misleading: DWR coatings wear off rapidly with use. When this happens, the polyurethane will still keep the tent underneath dry, but the fly will soak up water, which in the case of nylon will induce stretch that compromises a taut pitch, and in either case will facilitate the growth of mold if not thoroughly dried. Aftermarket DWR treatments are available to rejuvenate the coating, but must be considered a frequent chore to remain effective.

A superb Hilleberg Soulo single-person tent, well-guyed and staked against Grand Canyon katabatic gusts.

There’s more. Polyurethane coatings formulated with a polyester base are subject to hydrolysis: stored damp, water molecules break down the polyester molecules. Ever pulled a tent out of storage and found it smelly and stuck to itself? That’s the (irreversible) result of hydrolysis. Polyester coatings made with polyether or polycarbonate bases resist hydrolysis much more effectively—but expect a blank look when you ask your outdoor-store sales clerk which is in the tent you’re considering.

Much, much better than polyurethane coating is silicone, which actually embeds into the fabric and strengthens it—in fact it would not be wrong to refer to such material as silicone-reinforced. A silicone-treated flysheet is so water repellent that a good shake will leave it practically dry. Some manufacturers combine a polyurethane coating on the underside of the fly with a silicone treatment on top—much better than PU/DWR, but not as good as double-impregnated silicone. Downsides? Cost—significantly higher than PU—and the fact that seam tape will not adhere to silicone; seams must be sealed with liquid sealant (you’ll need special repair tape for tears as well, although tears will be less likely in the first place, and less likely to migrate). It would not be exaggeration to say that if the fly of your tent is double-silicone-treated nylon or polyester, you can pretty much be assured the rest of the tent will be first-class as well. Since you can expect a silicone-treated tent to last far longer than one coated with polyurethane, it may well be less expensive in the long run.

Waterproof fabric is rated by something called hydrostatic head, which refers to the height reached by a column of water above a sample of fabric before it starts to seep through. The generally accepted minimum standard for a fabric to be considered waterproof is 1000mm; most flysheets exceed this by a substantial amount. Floor material—which is subjected to direct pressure against water—should exceed 3000mm.

Floor. Nylon—logically of a heavier denier than the canopy or fly—is the preferred material for tent floors, and almost all are polyurethane coated (exceptions include Stephenson and Terra Nova, see below). You want a ‘bathtub’ floor, which means the floor material extends a few inches up the side of the otherwise breathable canopy, to prevent pooled or running water gaining entrance. Logically, the fewer seams in the floor, the better. My old Marmot Taku had a floor with no seams at all, but few types of suitable fabric come in sufficient widths any more, so most tents will have one seam up the middle, which should be taped from the factory or sealed by the owner.

Canopy. The inner wall of most tents is non-waterproof, breathable nylon, to help dispel condensation. While this helps, flow-through ventilation is much more effective at minimizing both condensation and related cold-weather internal frost. Ideally you want a ‘chimney’ effect, in which cool air is drawn in near the floor, and warm, moist air rises naturally and exits via high vents. Tunnel-shaped tents with one end higher than the other excell at flow-through ventilation; dome tents with no peak vent are very poor at it.

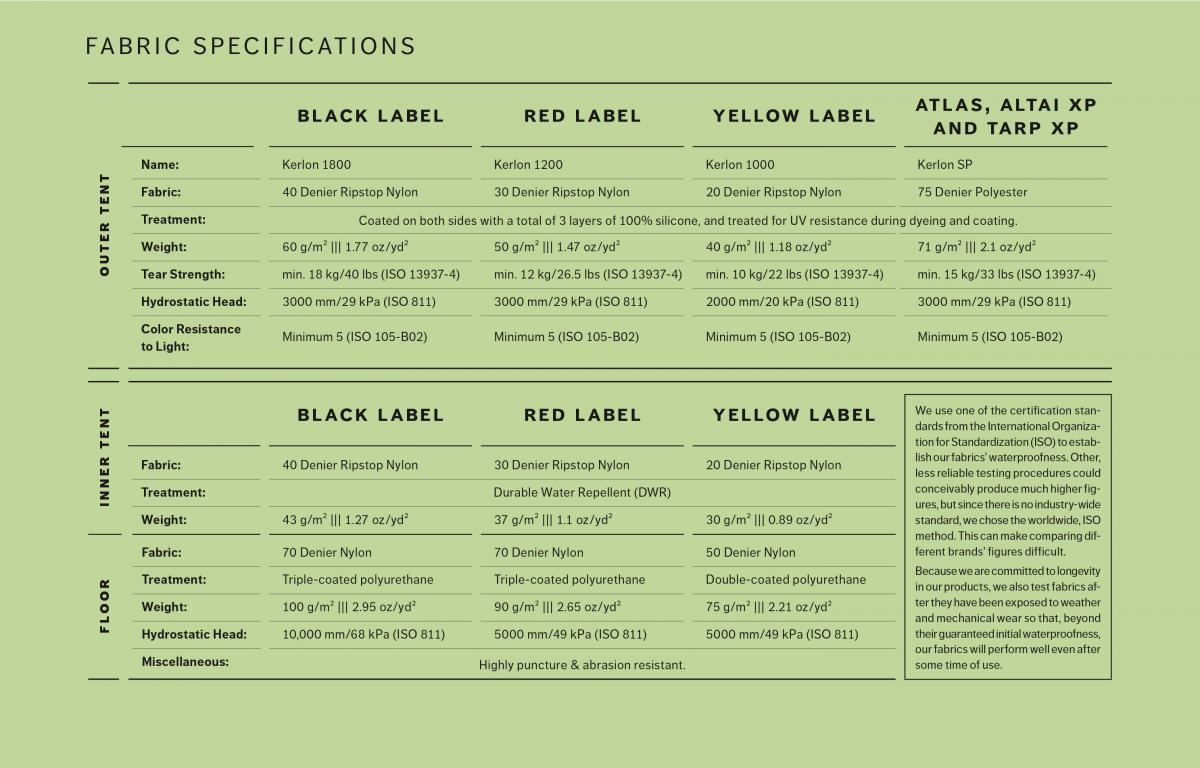

A chart from Hilleberg showing various fabrics used in their tents.

So-called three-season tents will have fewer, sometimes smaller-diameter, poles, and a canopy with larger areas of screen (no-see-um netting); it might even be all screen so that on clear, balmy nights one can leave off the fly and remain protected from flying and crawling bugs while enjoying the breeze. A four-season tent needs to be sturdier to withstand storm-force winds and snow loads, so will have more and thicker poles, plus tie-outs to help anchor the structure. Many four-season tents have large screen sections that can be closed off when necessary, making them adept at all-season use.

Size. There are no universal standards that quantify a ‘one-person’ versus ‘two-person’ versus ‘three-person’, etc. tents. Generally speaking, 30 square feet is minimum for two people, 35 or 40 is more comfortable, and 45 or even 50 is not out of the question for a couple if you might be tentbound for periods due to extended rain. Floor area is not the only arbiter of comfort: A 40-square-foot dome tent with near-vertical walls will be much more spacious than a 40-square-foot A-frame tent with steeply sloped walls. Vestibules help a great deal to keep boots and stoves out of the living area. Poled vestibules, which create more overhead clearance, are better for cooking, to keep heat away from the fabric.

Free-standing tents are easy to move around if you decide on a new view (or to upend and shake out to clean), and nice in the few locations (such as slickrock) where it is simply impossible to use stakes, but otherwise the feature is highly overrated. All tents should be staked down at all times. Two sleeping bags and a couple of air mattresses do not comprise sufficient ballast—I watched a tent thusly weighted clear the top of a saguaro cactus by ten feet after a brisk gust off the Sea of Cortez caught it.

Very, very few tents come with stakes that are worth a damn. Worst are the soft round aluminum pegs with a hook on the end; I regularly demonstrate the value of these by bending them in my teeth. Any stake that is round in cross section will have less holding power than one with more frontal area to resist sideways pull. Tempered alloy stakes of either T or V cross-section, included with high-quality tents from Hilleberg, for example, are pretty good; however even these are still too small to properly anchor a tent in anything less than perfect holding ground. I wrote about a good aftermarket stake here.

Geodesic dome tents—with a pole structure that creates triangulated reinforcement—are generally more intrinsically stable in side winds than tunnel tents employing parallel hooped poles. But the latter can be superbly stable when pitched end-on into the prevailing breeze, and will do just fine in a crosswind if guyed out properly. My Marmot Taku seemed simply immune to winds from the back; it would just hunker down and tauten and I’d sleep like a babe. Until a client woke me up . . .

A North Face VE25, one of the original geodesic dome tents.

Speaking of the Taku . . . single-wall tents, which typically employ a canopy of some waterproof/breathable laminate, are attractive in their light weight and simplicity, but generally of limited value outside mountaineering expeditions, due to the hugely increased risk of condensation. Sit inside a single-wall dome tent in a cold rain and you might think the fabric itself is leaking, there’ll be so much condensation. (The steeply sloped Taku had such excellent chimney ventilation this was not a problem.)

So, which tents to look at? Companies such as Mountain Hardwear, Marmot, Sierra Designs, Nemo, Kelty, MSR, and Big Agnes make tents of good quality, using excellent aluminum poles but standard PU-coated fly material. Redverz and Lone Rider make nearly identical tents designed around a ‘bikeport’ that shelters a full-size motorcycle.

Want to step up in quality? Look at Hilleberg, the Swedish maker of superb fabric shelters that justify their high initial cost with top-notch construction and materials, including triple-coated silicone fly material. My Hilleberg Staika is a comfortable two-person dome with dual vestibules and entrances, and enough stability (and auxiliary guy lines) to anchor it in anything short of a storm with a name. Yet both doors have screen panels large enough to make the tent fully summer-functional. It’s also completely free-standing, even with the vestibules. My bicycling tent is an Anjan 2 GT, a four-pound tunnel tent with a poled front vestibule large enough to cook or bathe in. If I were off on a really extended journey, a Hilleberg tent would be my first choice.

British company Terra Nova also makes very high-quality tents, including the Laser Photon 2, a (tight) two-person tent that weighs just two pounds. I note that some of their models use PU-coating—hard to justify given the premium prices. Check the specs on the model that interests you.

Iconoclastic nudist tentmaker Jack Stephenson has been using hyperlight silicone-coated nylon in his tents for decades, along with oversize, thin-wall, pre-bent poles that are much stronger than their scant heft would suggest. The result is a spacious two-person tent that weighs three pounds—lighter for its floor area than any other four-season tent of which I’m aware. Sadly there is no vestibule—although the prickly Stephenson will scoff if you suggest his products are less than perfect.

Finally, at the Overland Expo East I was introduced to local (as in Asheville) tent maker LightHeart Gear, sewing featherweight tents originally designed for trekkers, and employing siliconized material and either trekking poles or standard aluminum replacements. I’ve not yet tested one, but the display models certainly held up to the wet Expo weather with no trouble. Worth checking out.